My shopping cart

Your cart is currently empty.

Continue ShoppingThe Early Years

Mrs. Stewart’s® Bluing was born in the early 1880s. “MSB” owes its existence to a peddler and his mother-in-law, a marginally successful Five and Ten Cent store, and a fireworks explosion. From the beginning, Mrs. Stewart’s® journey has been an interesting one!

In the late 1870s, Al Stewart, a traveling salesman for a Chicago wholesale grocer, was a familiar figure in Iowa and southern Minnesota. In his market basket full of samples, he always carried a bottle of Mrs. Stewart’s® Bluing, which he made in his home with his family assisting him according to a formula he had acquired.

Meanwhile, Luther Ford, a young silk salesman, moved to Minneapolis where he started the first “Five and Ten Cent Bazaar” west of Pittsburgh. Business was not highly successful and so he began a wholesale business, carrying notions, toys, and fireworks.

Al Stewart and Luther Ford crossed paths when Mr. Stewart began searching for someone to manufacture his bluing for him. Following a spectacular (but accidental) eruption of fireworks in the Five and Ten Cent store, Mr. Ford realized the potential of a (safer) future in the bluing business! Al Stewart sold Luther Ford the rights to Mrs. Stewart’s® Bluing, and the first documented sale of Mrs. Stewart’s® Bluing was logged on July 30, 1883. Mr. Ford quickly made plans to extend distribution across the region.

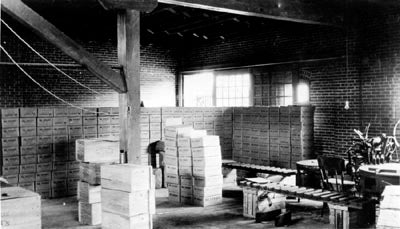

Facilities and equipment used in manufacturing in the late 1800s were primitive. The ceiling in the first basement factory was so low, holes had to be made in the floor so the employees had a place for their feet to hang down. Filling was done from wooden barrels with a rubber hose. Corks were pounded in with a small mallet, and each bottle was dipped in hot sealing wax as the corks didn’t always fit into the slightly irregularly shaped hand-blown bottles. Labeling was done by hand using paste. Bottles were packed in sawdust in wooden cases or in barrels. Stock was stored and production stopped during the winter, until a later date when a heated manufacturing building was obtained.

Early Competition

Around the turn of the century, Mrs. Stewart’s® Bluing had lots of competition from other “blues”. Mrs. Stewart’s® was such a superior product that other companies were constantly trying to imitate it. Labels were copied and even reused in many cases. Loyal Mrs. Stewart’s® Bluing users were not easily fooled, however, and all of these “masqueraders” eventually faded away, leaving Mrs. Stewart’s® Bluing in a class by itself!

Around the turn of the century, Mrs. Stewart’s® Bluing had lots of competition from other “blues”. Mrs. Stewart’s® was such a superior product that other companies were constantly trying to imitate it. Labels were copied and even reused in many cases. Loyal Mrs. Stewart’s® Bluing users were not easily fooled, however, and all of these “masqueraders” eventually faded away, leaving Mrs. Stewart’s® Bluing in a class by itself!

Bluing was manufactured by some competitors in stick, cube, powder and ball form. Mrs. Stewart’s® Bluing has been a liquid from the beginning. We have never marketed MSB in any other form, and, as incredible as it may seem, it is essentially the same product today it was way back in 1883! (As the saying goes, “If it ain’t broke, don’t fix it!”)

Growing the Business

Mrs. Stewart’s® Bluing grew slowly until 1910 when Luther Ford’s son Allyn, fresh from college, came into the business. He saw great potential in bluing and resolved to put his best efforts into expanding distribution. Allyn’s brother, Robert, eventually left his teaching career and the brothers turned all their energy to the Mrs. Stewart’s® Bluing enterprise.

Mrs. Stewart’s® Bluing grew slowly until 1910 when Luther Ford’s son Allyn, fresh from college, came into the business. He saw great potential in bluing and resolved to put his best efforts into expanding distribution. Allyn’s brother, Robert, eventually left his teaching career and the brothers turned all their energy to the Mrs. Stewart’s® Bluing enterprise.

By 1925, additional factories existed in Portland, San Francisco, St. Louis, Pasadena and in Winnipeg, Manitoba. Distribution was nationwide across the United States and Canada. Today, all production takes place in our updated Bloomington, Minnesota facility. Distribution of MSB is handled by public warehouses in key market areas and by our broker network.

By 1925, additional factories existed in Portland, San Francisco, St. Louis, Pasadena and in Winnipeg, Manitoba. Distribution was nationwide across the United States and Canada. Today, all production takes place in our updated Bloomington, Minnesota facility. Distribution of MSB is handled by public warehouses in key market areas and by our broker network.

From Salesmen to Grocery Brokers

When business started booming, salesmen were hired who worked directly out of the Minneapolis office. In 1918, this method of selling was replaced by the appointment of food or grocery brokers. It was this switch to food brokers which accounted for the rapid and steady growth of the Mrs. Stewart’s® Bluing business. Since then, MSB has been represented across the United States and Canada by brokers. Much of the credit for the good health and longevity of the business belongs to these devoted brokers, many of whom, over the years, have become personal friends as well as business colleagues!

In 1946, with Mrs. Stewart’s® Bluing sales at a high point, Robert Ford’s son Luther (named for his grandfather) returned to Minneapolis and by the mid 1950s, he had taken over the business from his father and his uncle. He was head of the firm during the 1960s and 1970s. In August, 1955, Ken Norman was hired as Manager of Production and Purchasing. In the late 1970s, Ken bought the company from Luther Ford. Ken’s son, Brad, joined in the business in 1974 and took over ownership in 1995. He took on co-owner, Jeff Olson, who became sole owner in 2013. In 1986, the business was moved from downtown Minneapolis to suburban Bloomington, where it remains today (2015). From 1883 to the present time, production and distribution of MSB has been and remains an old-fashioned “family” business.

Highly Sought-After MSB Bottles

The earliest Mrs. Stewart’s® Bluing bottles were hand-blown. Starting in about 1907, bottles were manufactured on automatic bottle-blowing machines. The words “This contains Mrs. Stewart’s® Bluing” were embossed into the face of the bottles, as insurance against unauthorized reuse by others.

The earliest Mrs. Stewart’s® Bluing bottles were hand-blown. Starting in about 1907, bottles were manufactured on automatic bottle-blowing machines. The words “This contains Mrs. Stewart’s® Bluing” were embossed into the face of the bottles, as insurance against unauthorized reuse by others.

Around 1920, the embossing on the bottle face was discontinued and replaced with a similar embossment around the shoulder of the bottle. In the spring of 1933, Robert Ford’s newly designed machinery was used to apply hot wax around the rim of each bottle to prevent the liquid from running down the side of the bottle when dispensing the product. This soon became the patented “No-Drip” process. That summer, the words “No-Drip” also appeared in gold lettering on the MSB labels in honor of the 50th anniversary of the Ford/Stewart connection. Bottles were capped with imported Portuguese corks which were specially made for MSB and put into red wooden tops; the two parts of each closure were hand-glued together. The top of each bottle cork had the words “No-Drip Bluing” imprinted by hand.

Early in the 1960s, a new development in liquid dispensing became available in the form of a plastic dispensing “fitment” inserted into the bottle allowing it to be dispensed by the drop.

Early in the 1960s, a new development in liquid dispensing became available in the form of a plastic dispensing “fitment” inserted into the bottle allowing it to be dispensed by the drop.

Starting in 1962 in the U.S. and in 1965 in Canada, plastic screw caps replaced the wooden corks which were previously used. Beginning in the early 1970s, our company began phasing out glass bottles and introduced plastic.

Today, MSB is packaged exclusively in recyclable plastic bottles.

Today, MSB is packaged exclusively in recyclable plastic bottles.

For almost a half-century, Mrs. Stewart’s® Bluing was put up in just a ten-ounce size and retailed for 15¢ to 25¢. The Depression economy of the 1930s prompted the production of the “Dime-Size” glass bottle for some years. The “Dime-Size” bottle actually underwent three different size changes and didn’t always retail for a dime. At first, the “Dime-Size” was a squat 3-ounce, then a tall and slender 3 1/2-ounce, and finally, an oval 4-ounce which was sold through the mid-1970s.

Mrs. Stewart’s® Bluing bottles, particularly the oldest ones with the long-ago replaced red wooden-topped corks, are now highly sought-after antique collectors’ items. Requests are often received for these old bottles, but, alas, there are few to be found nowadays! Collectors scour the country’s antique shops in hopes of purchasing one for their very own, or check out Grandma’s cellar hoping for a lucky find!

History of the Bluing Process

Before the automatic washer arrived, the process for bluing white fabric in the home consisted of soaking or washing the clothing in hot soapy water, usually in a large kettle over a stove or in a wash tub, then rinsing the clothing thoroughly in another kettle-often two times. Finally, a “bluing” kettle was prepared — cool water with just enough bluing added to make the water a light, sky-blue color — in which the clothing was simply dipped in briefly and removed, then hung to dry.

“Today, bluing can be used in the wash cycle or the final rinse cycle in most top and front-loading machines to restore fabric to the “whitest white”.

WHO is she?

The first bottles of Mrs. Stewart’s® Bluing probably carried a homemade, handwritten label. Eventually, Mr. Stewart decided to have his labels commercially done. The printer he contacted recommended that a label be used which featured a picture of an older woman, as this would help sales to increase! He asked his wife for a picture of herself to use, but she, so the story goes, refused to have her picture used on the label of a bluing bottle. He plucked a photograph of his mother-in-law from the mantle and promptly delivered it to the printer. So, that no-nonsense granny who appears on every bottle of Mrs. Stewart’s® Bluing throughout North America is none other than Mrs. Stewart’s® mother, the real Mrs. Stewart thus losing her opportunity to be immortalized!

MSB label design has remained fairly constant from the early days to the present, with one notable exception. On the advice of an advertising agency in the early 1970s, the “stern granny” look of Mrs. Stewart on the label was replaced with the pleasant face of a silver-haired, “with it” looking, wrinkle-free, smiling woman in a stylish hairdo. Consumers went on a rampage! A flood of mail came in from all across North America wanting Mrs. Stewart back! And they got her back, too! Over the years, Mrs. Stewart has undergone several very minor changes, but never again will consumers be surprised with a “stranger” on the label of Mrs. Stewart’s® Bluing!

How did MSB get to be over 140 years old?

Although MSB has been used most commonly to whiten white fabric that has grayed or yellowed with age, consumers have discovered additional uses for bluing since day one! Remember the Salt Crystal Garden (also called a “Depression Flower” or “Coal Garden”)? A favorite family or school science project for all ages, bluing is an essential ingredient in growing this beloved crystal formation! We continue to sell MSB to schools, scout packs, science supply houses, and consumers for this use.

We know of no other product, laundry or otherwise, that has as wide a variety of other uses. Look at some of the other reasons consumers purchase MSB!

And, while the company has done some small-time advertising in magazines and newspapers here and there, we’ve never launched television or infomercial campaigns. Word of Mouth has always been our preferred method of advertising. It’s fail-proof.